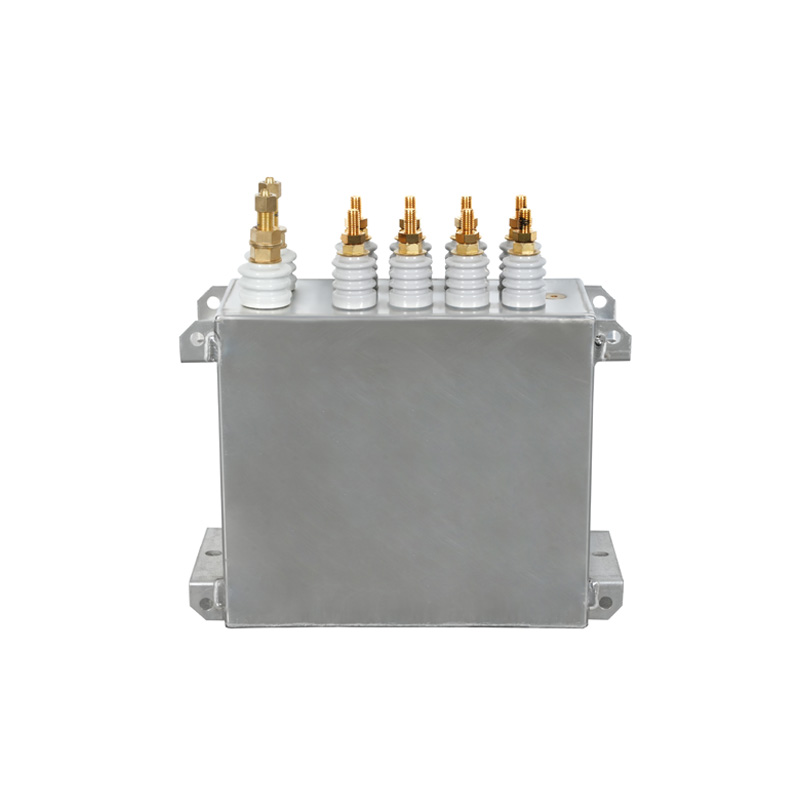

Toilleoir teasa ionduchtaithe uisce-fuaraithe

Toilleoir teasa ionduchtaithe uisce-fuaraithe

Toilleoir teasa ionduchtaithe aer-fhuaraithe

Toilleoir teasa ionduchtaithe aer-fhuaraithe

RAM 2200V 3960KVAR 3000Hz Minicíocht Meánach Toilleoirí Teasa Teasa

RAM 2200V 3960KVAR 3000Hz Minicíocht Meánach Toilleoirí Teasa Teasa

I réimse na leictreonaice cumhachta, tá sé ríthábhachtach sruth díreach glan ...

foghlaim níos móToilleoirí Umar Téitheoir Ionduchtúcháin ról ríthábhachtach a im...

foghlaim níos móTuiscint Toilleoir Uisce Fuaraithe Bunús Is dul chun cinn ríthábhac...

foghlaim níos móToilleoirí Ardvoltais a Thuiscint — Bunús agus Tábhacht Cad is Toilleoir A...

foghlaim níos móI saol casta na leictreonaice nua-aimseartha, is beag teip na gcomhpháirteann...

foghlaim níos móAn Inneall Neamhfheicthe: Cén Fáth a bhfuil Toilleoirí Fuarú Uisce ríthábhach...

foghlaim níos móTá foireann láidir T&F againn, agus is féidir linn táirgí a fhorbairt agus a tháirgeadh de réir na líníochtaí nó na samplaí a thairg na custaiméirí. $ $

Tá dhá cheann dár dteilgcheártaí réitigh féin againn agus monarcha meaisínithe CNC amháin. Mar sin is féidir linn an praghas agus na táirgí a thairiscint go díreach. $ $

Tá ár saotharlann tástála féin againn agus ár dtrealamh cigireachta ardleibhéil agus iomlán, ar féidir linn cáilíocht na dtáirgí a chinntiú. $ $

Sáraíonn ár n -aschur bliantúil 20,000 píosa, ar féidir leis freastal ar riachtanais na gcustaiméirí a bhfuil méideanna éagsúla ceannaigh acu. $ $

Dírímid ar tháirgí ardchaighdeáin a fhorbairt do mhargaí barr-deiridh. Tá ár dtáirgí ag teacht le caighdeáin idirnáisiúnta agus déantar iad a onnmhairiú go dtí an Eoraip, Meiriceá, an tSeapáin, agus cinn scríbe eile ar fud an domhain. $ $

Tá foireann seirbhíse iar-díolacháin ghairmiúil ag an gcuideachta le pearsanra ardchaighdeáin, taithí theicniúil fhairsing, agus trealamh tástála chun cinn. Ag cloí leis an dearcadh eolaíoch ar fhorbairt, bíonn dlúthbhaint ag an gcuideachta le húsáideoirí, bíonn sí i mbun malartuithe teicniúla dlútha, agus soláthraíonn sí seirbhísí táirgthe saincheaptha "duine le duine". Saothraíonn an chuideachta táirgí pearsantaithe agus difreáilte, ag athrú a tionscail déantúsaíochta ó cheann atá dírithe ar tháirgeadh go ceann atá dírithe ar sheirbhís. Trí mheicníocht meastóireachta úsáide táirgí, cuireann an chuideachta tionscadail sástachta úsáideoirí chun cinn, agus déanann sí iarracht gan aon ghearáin úsáideoirí tar éis díolacháin a bhaint amach.

Heat exchange principle: Water-cooled induction heater tank capacitors generate a lot of heat when working. The design of the cooling channel is based on the principle of heat exchange. By allowing cooling water to flow in the channel, the heat generated by the capacitor is absorbed, thereby reducing the temperature of the capacitor. Jiande Antai Power Capacitor Co., Ltd. has 40 years of professional experience. When designing cooling channels, it fully considers the efficiency of heat exchange to ensure that the product can operate stably under various working conditions. The induction heating melting capacitors and other products it produces have effectively solved the heat dissipation problem through reasonable cooling channel design, ensuring the excellent performance of the products, which is one of the reasons why its products have won wide recognition and trust from domestic and foreign customers.

Channel layout: The cooling channel is usually laid out around the heating element of the capacitor to achieve uniform heat dissipation. Common layout methods include spiral and parallel. The spiral channel enables the cooling water to flow in a spiral shape around the capacitor shell, increasing the contact area and contact time between the cooling water and the capacitor, and improving the heat exchange efficiency. The parallel channel is easy to process and install, and can ensure that the cooling water is evenly distributed in a certain area.

Channel size: The size of the cooling channel has an important influence on the cooling effect. If the channel diameter is too large, the cooling water flow rate is large, but the flow rate is low, and the heat exchange efficiency may not be high; if the channel diameter is too small, the flow rate is high, but the water resistance increases, which may lead to an increase in the power of the water pump and easy blockage. Generally speaking, the channel size needs to be determined based on factors such as the heat generation of the capacitor, the flow rate and pressure of the cooling water. During the production process, Jiande Antai Power Capacitor Co., Ltd. will use its own testing laboratory and advanced and complete testing equipment to test cooling channels of different sizes to find the best design solution to ensure product quality.

Optimize the channel inlet design: In order to make the cooling water enter the cooling channel evenly, the design of the inlet is crucial. A diffusion-type inlet can be used to allow the water flow to be evenly dispersed when entering the channel to avoid the situation where the local flow rate is too high or too low. At the same time, a guide plate or diverter is set at the inlet to guide the water flow to each branch channel to ensure the uniform distribution of the water flow.

Adopt reasonable channel shape and structure: The shape and structure of the channel will affect the flow characteristics of the water flow. For example, the use of smooth inner walls can reduce the resistance of the water flow and avoid turbulence or vortexes in the water flow. In addition, setting appropriate spoiler elements in the channel, such as ribs or protrusions, can increase the disturbance of the water flow and improve the heat exchange efficiency, but at the same time, care should be taken to avoid uneven water flow caused by spoiler elements. When designing cooling channels, the R&D team of Jiande Antai Power Capacitor Co., Ltd. will comprehensively consider the shape, structure and arrangement of spoiler elements of the channel to achieve the best cooling effect and water flow uniformity.

Balance channel resistance: In order to ensure that the cooling water flows evenly in each channel, it is necessary to balance the resistance of the channel. For longer or more curved channels, the cross-sectional area of the channel can be appropriately increased to reduce the resistance; for shorter or straight channels, the cross-sectional area can be appropriately reduced to make the resistance of each channel roughly equal. This ensures that the flow distribution of cooling water in different channels is uniform.

Install flow control devices: Installing flow control devices such as flow control valves or flow meters in the cooling system can monitor and adjust the flow of cooling water in real time. By precisely controlling the cooling water flow rate of each channel according to the operating temperature and actual needs of the capacitor, uniform heat dissipation can be achieved.

Regular maintenance and cleaning: Scale, impurities, etc. may accumulate in the cooling channel, affecting the uniformity of the water flow and the heat exchange efficiency. Therefore, the cooling system needs to be maintained and cleaned regularly to keep the channel clean and unobstructed.